邵陽Stopper, Long Nozzle, Submerged Nozzle

The stopper is mainly used for opening and closing the flow control of the tundish. it is installed in the tundish, and the flow

rate of the molten steel entering the casting mold is adjusted by controlling the position of the stopper head to the tundish nozzle.

The long nozzle is a product that connects the ladle and the tundish. When the molten steel casting from ladle into the tundish

through the long nozzle, it can prevent the molten steel from oxidation and splashing.

The submerged nozzle is to protect the molten steel from being oxidized by ambient air when flowing from tundish into the

casting mold, and to uniformly distribute the molten steel into the casting mold and control the flow state of the molten steel.

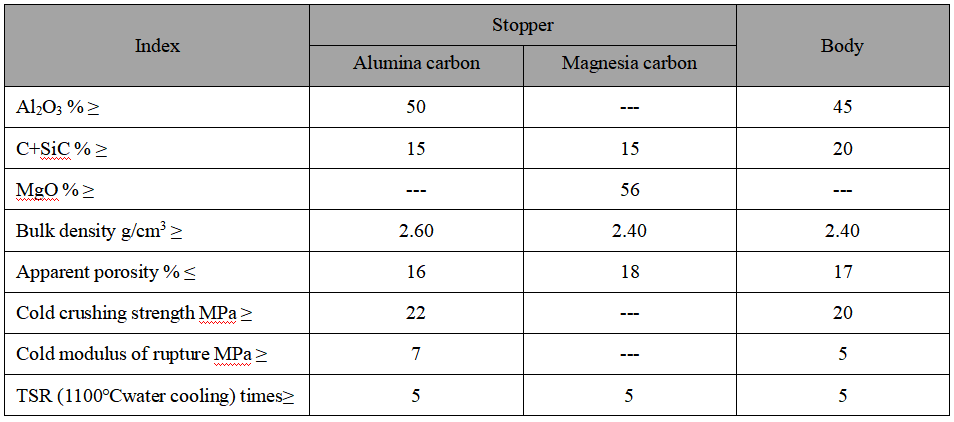

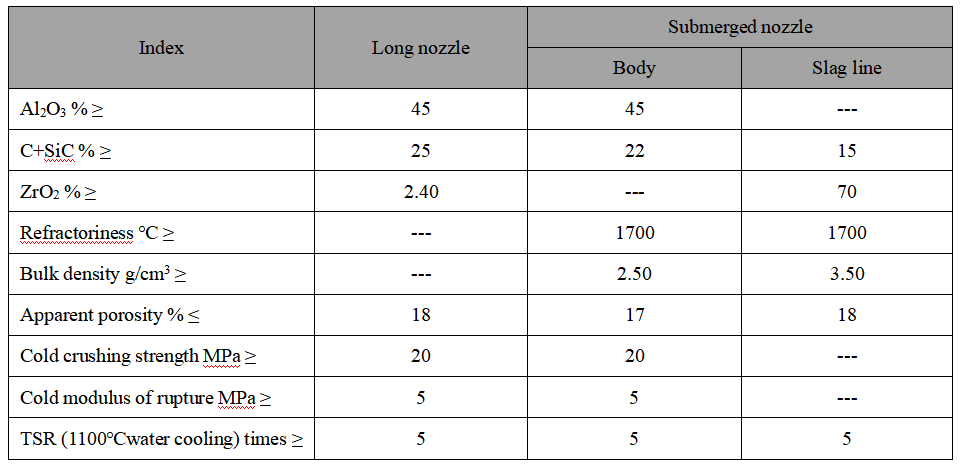

Main physical and chemical performance index: